SMT solar panels utilize Surface Mount Technology to solder solar cells onto PCBA. SMT, an abbreviation for Surface Mount Technology, refers to the technique of soldering electronic components onto the surface of circuit boards. The advantages of SMT solar panels include the ability to produce smaller-sized panels, suitable for mass production. However, SMT solar panels are limited in power and primarily target small power applications.

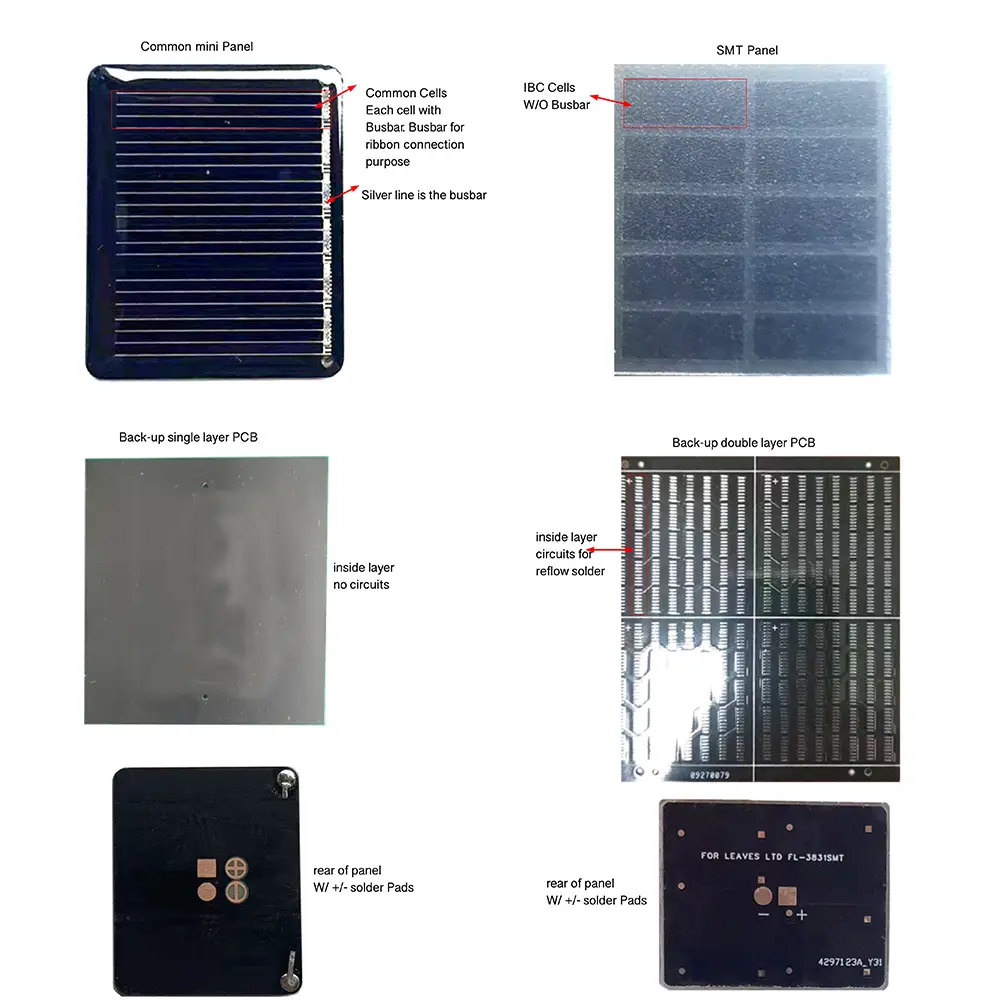

Typically, SMT solar panels utilize IBC solar cells, like Sunpower high-efficiency solar cells or China made IBC solar cells, boasting an efficiency of up to 23%. IBC solar cells, characterized by their rear-side positive and negative terminals and closely spaced terminals within each group, can be cut into smaller sizes, allowing for higher power output compared to traditional solar panels in the same area. Meanwhile, allowing for the cell to be cut into smaller sizes. The traditional solar cell with busbar can not be used.

The disadvantage of SMT technology is the high cost of sample production, which includes expenses such as SMT machine and stencil fees, making it less cost-effective for small-batch orders. Nevertheless, it is suitable for very small-sized solar panels requiring high output voltages, where traditional cell cutting and soldering processes are not feasible. SMT panels can achieve thinner profiles, as thin as 1mm, and smaller sizes, such as 10mm x 10mm or smaller. Moreover, SMT can be applied to Flexible Printed Circuits (FPCs), providing certain flexible functionalities.